APEX Bharat coil heaters utilize a proprietary internal micro-coil design that delivers high watt densities to concentrated areas such as plastics injection molding nozzles,small heat transfer pipes, hot knives, and concentrated chambers. Coil heaters can be tightly wound or the coil can be distributed to provide a uniform heat pattern over a wide area. Whether you require a standard size for your plastic machinery or a customer configuration for wafer processing, APEX Bharat can specify the design you require.

APEX Bharat square section coil heater has been developed to meet the growing demands for a completely sealed heater, able to operate at the ever increasing temperatures required by todays modern machines. It’s square section tubular construction, combines flexibility in design with ruggedness and durability in operation, giving it many advantages over the standard Mica nozzle heater. Capable of working up to 750° C , the coil heater can last up to 10 times the life of a Mica nozzle heater, saving down time and maintenance costs and reducing the number of mica nozzle heaters used, giving our customers a purchase cost saving. Available in 3mm square section, complete with or without a built type J or K thermocouple, or a 3.3mm square section heater with the option of a thermocouple

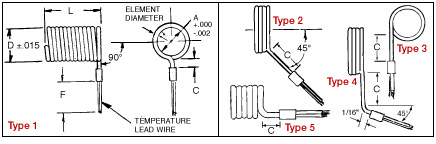

Coil and nozzle heater are available with standard high temperature leads (450°F/250°C), teflon leads, flexible stainless steel braided lead protection or with stainless steel armor cable.

COIL AND NOZZLE HEATER – APPLICATIONS:

- Plastic injection molding equipment

- Thin Walled Container Moulds

- Hot runner molds

COIL AND NOZZLE HEATER – ORDER AND ENQUIRIES:

- Inside Diameter of Band

- Wattage

- Dimensional Sketch or Sample

- Width of heater

- Lead Length and Termination Style

- Quantity